How to prevent microcentrifuge tube lids from breaking during centrifugation?

When performing DNA cleanup procedures such as PCR cleanup or plasmid preparation, samples are often collected in 1.5 mL microcentrifuge tubes. Improper tube placement can lead to excessive lid tension, increasing the risk of breakage or sample contamination.

Solution: position tubes in pairs

Place tubes in pairs with the lids facing away from each other. This simple adjustment ensures a secure fit, reduces stress on the caps, and minimizes the risk of accidental damage during centrifugation.

How do you properly balance a centrifuge to prevent rotor damage and sample loss?

When preparing samples for centrifugation, whether for DNA purification, PCR cleanup, or other lab protocols, it’s not just about loading tubes and pressing “start.” A well-balanced rotor is essential for both sample integrity and the longevity of your centrifuge.

An unbalanced load can cause excessive vibration, loud noise, and even catastrophic rotor failure. This can result in broken tubes, lost samples, costly repairs, or dangerous accidents. Proper balancing also ensures optimal sample separation and consistent pellet formation.

Solution: always balance mass and volume

- Always balance tubes by weight, not just by sight. Two tubes filled to the same volume may differ in mass if their solutions have different densities. Use a digital scale to check that your tube pairs match in mass as closely as possible.

- Place tubes symmetrically across from each other in the rotor. For example, if you have four samples, fill the rotor in a cross pattern. In microcentrifuges with more slots, arrange all tubes evenly around the centre to maintain balance.

- If you have an odd number of samples, prepare a balance tube (“dummy”) using the same type of tube filled with water or buffer to match the mass of your heaviest sample. Even one extra tube can make all the difference in achieving a smooth, safe spin

How to you select the right rotor and tubes for your centrifuge?

Choosing the correct rotor and tubes is essential for safe and efficient centrifugation. Using incompatible components can lead to poor separation, tube breakage, or even rotor failure.

Solution: match rotor and tube specifications

- Check rotor type and capacity: swing-out rotors are ideal for density gradient separations, while fixed-angle rotors work best for pelleting

- Verify tube compatibility: ensure tubes are rated for the maximum speed and temperature of your centrifuge. Using tubes outside their specifications can cause cracks or leaks

- Consider material and closure: polypropylene tubes are common for biological samples, while polycarbonate tubes handle higher speeds. Choose caps that seal securely under centrifugal force

- Follow manufacturer guidelines: always consult the centrifuge and rotor manuals for approved tube types and maximum load limits

Our centrifuges

Microcentrifuge Kestrel

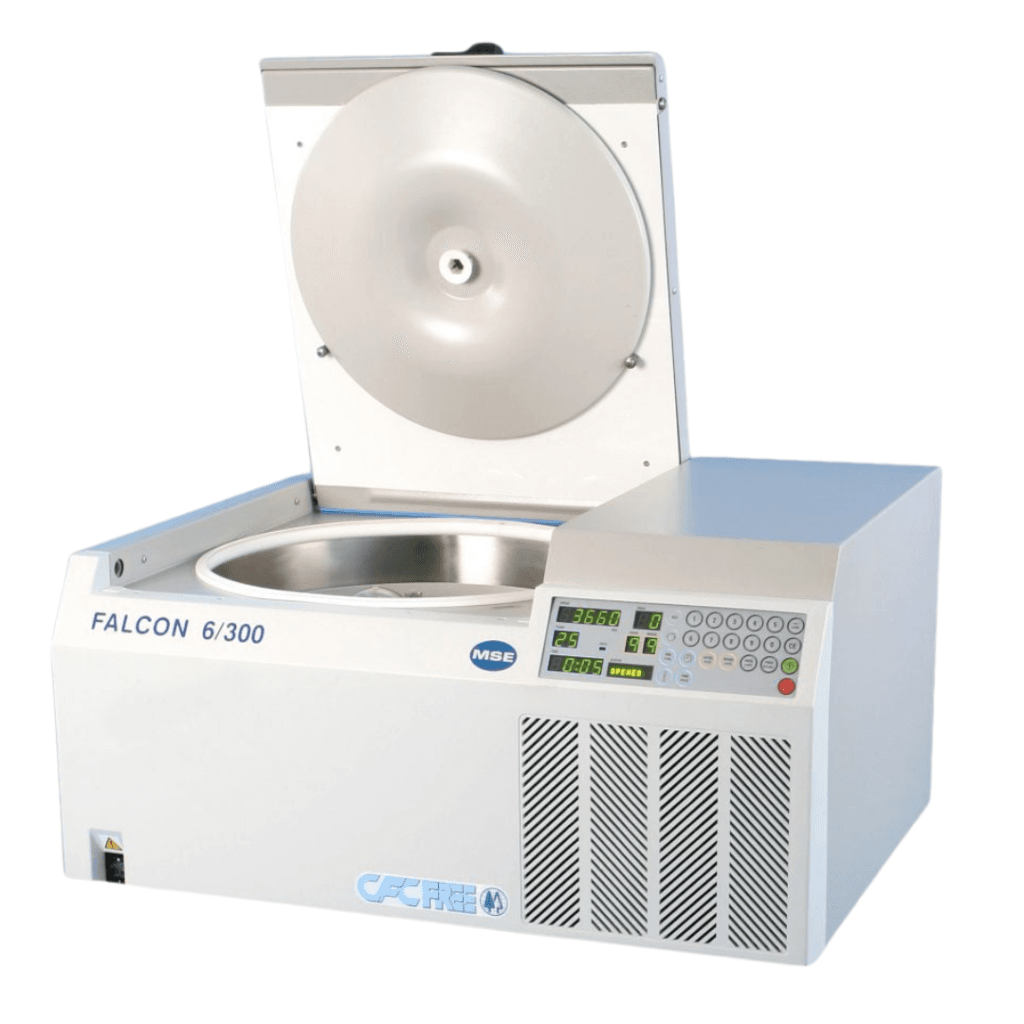

Falcon benchtop centrifuge Powerful induction drive, 3-litre capacity centrifuge without refrigeration

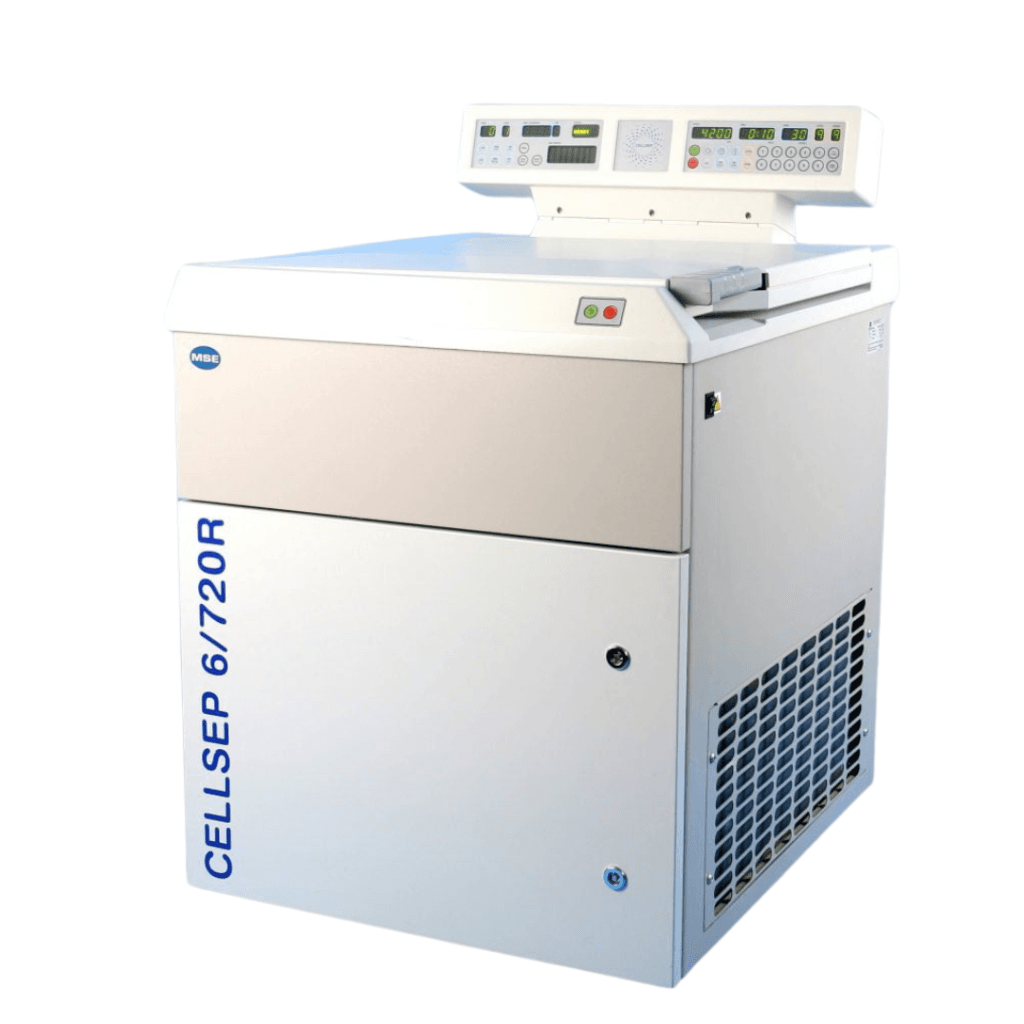

High-speed centrifuges

How can we help you

Do you have another question? Fill out the form below and we’ll be happy to assist you.